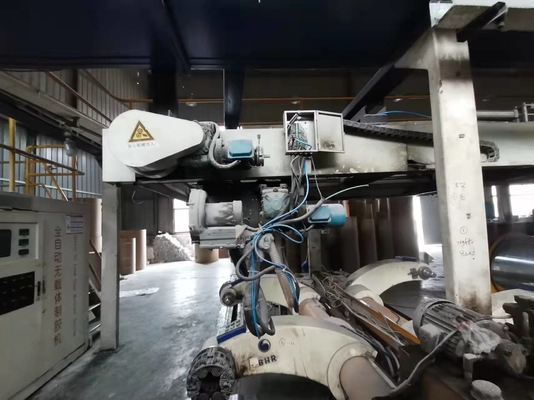

Iso Cardboard Making Machine Splicer In Packaging Industry

Product Details:

| Place of Origin: | CN |

| Brand Name: | Aomei |

| Certification: | ISO9001 |

| Model Number: | AoMei-1800 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 1000~8000 USD |

| Packaging Details: | plastic film |

| Delivery Time: | 45 days |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 20 sets per month |

|

Detail Information |

|||

| Voltage: | 220v/380v/440v,220V/380VCan Be Customized According To The Customer | Condition: | New |

|---|---|---|---|

| Type: | Packaging Line | After-sales Service Provided: | Online Support |

| Automatic Grade: | Automatic | Weight: | 800--2000kg |

| Dimension(l*w*h): | Depends On Configurations | Certification: | ISO9001 |

| Driven Type: | Hydraulic | Application: | Machinery & Hardware,Beverage,Food,Chemical |

| Packaging Material: | Plastic,Paper | Packaging Type: | Cartons,Film |

| Warranty: | 2 Years | Name: | Packaging Line |

| Usage: | Making Carton | ||

| High Light: | splicer cardboard making machine,packaging industry cardboard making machine,splicer cardboard box making machine |

||

Product Description

The Basic Principles Of Splicer In Corrugated Packaging Industry

The Basic Principles Of Splicer In Corrugated Packaging Industry

Free Roll: Before the paper web leaves splicer, it is running back and forth between the immovable guide roller and guide roller of the storage frame on the side of the paper outlet of the machine.In this way in the storage rack to form a paper storage. In the process of paper splicing,the free roller moves towards the paper outlet side of the machine so as to release the paper web stored therein for continuous production. After that,the storage rack is moved back to the other end of the machine and the paper webare restocked.