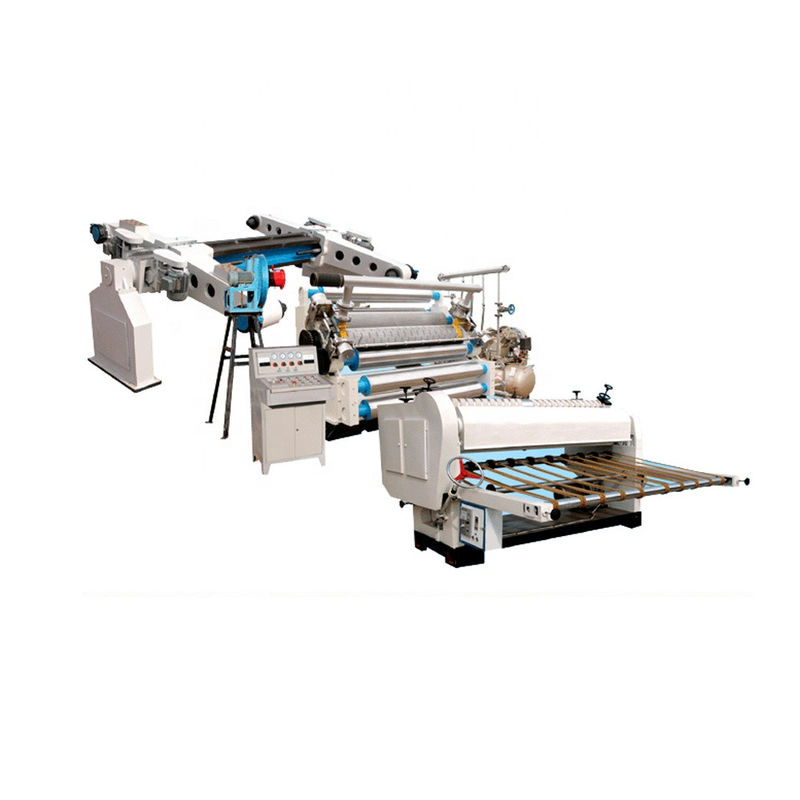

2 ply corrugated paperboard machine line single facer corrugated production line

Product Details:

| Place of Origin: | China |

| Brand Name: | Aomei |

| Certification: | ISO CE SGS |

| Model Number: | AD-2 Ply corrugated production line |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | 1000 |

| Packaging Details: | as per need |

| Delivery Time: | 35 days |

| Payment Terms: | D/A, D/P, T/T, Western Union |

| Supply Ability: | 1000sets |

|

Detail Information |

|||

| Automatic Grade: | Automatic, Semi-Automatic, Other | Voltage: | 380V 50HZ, 220v/380v/440v, 220V/380V, 380V50HZ, Determined By The State |

|---|---|---|---|

| Condition: | New, Used | After-sales Service Provided: | Engineers Available To Service Machinery Overseas, Video Technical Support, Field Maintenance And Repair Service, Field Installation, Online Support |

| Driven Type: | Electric, Manual, Hydraulic, Mechanical | Type: | Packaging Line, Absorb Type, Cardboard Making Machine, General |

| Warranty: | 1 Year, 12 Months, 2 Years, One Year, 3 Years | Packaging Material: | Plastic, Wood, Paper, Metal, Other |

| Certification: | CE, CE/ISO9001, CE Certification And ISSO2000, ISO, CE & ISO | Color: | 1-6 Color |

Product Description

AD-single face corrugated cardboard carton machine

AD-single face corrugated rolls machine is the most professional equipment

technical parameters as fllowing or custom as customer's demand.

Technical Parameter:

| Model | Working speed | Flute type | Heating System for Option |

| 1400 | 0-60 m/min | A/C/B/E | Oil /Electrical /steam heating |

| 1600 | 0-60 m/min | A/C/B/E | Oil /Electrical /steam heating |

| 1800 | 0-60 m/min | A/C/B/E | Oil /Electrical /steam gas heating |

| 2000 | 0-60 m/min | A/C/B/E | Oil /Electrical /steam heating |

Structure & Configuration:

1.Hydraulic mill roll stand

2.Single facer machine

3.

Hydraulic mill roll stand

Technical parameters:

1,the range of clamping paper:MAX1800mm MIN1000mm

2,clamping diameters:MAX1500mm MIN350mm

3,main shaft diameter of paper holder:242mm

4,gas source work pressure(Mpa):0.4---0.8Mpa

5,equipment size:Lmx4.3*Wmx1.8*Hmx1.6

6,single weight:MAX4000Kg

![]()

Hydraulic system parameters:

1.Work pressure(Mpa):16---18Mpa 2,lifting hydraulic cylinder:100×440mm

3.Clamping hydraulic cylinder:63×1300m

4,hydraulic station motor power:3KW --380V -- 50Hz

5,solenoid valve voltage:220V 50 Hz

Single facer Machine

*Technical parameters:

1,working width:1600mm 2,operation direction:left or right(Determined in accordance with the customer's facility)

3,design speed:80m/min 4,temperature range:160—220℃

5,air source:0.4—0.9Mpa 6,heating method:heating exchange

*Roller diameters parameters:

1,corrugated roller diameter:280mm 2,pressure roller diameter:284mm

3,glue roller diameter:215mm 4,preheat roller diameter:320mm

5. Lower preheat roller 215mm

*Powered motor parameters:

1,main drive motor:7.5KW rated voltage:380V 50Hz Continuous (S1) working standard

2,suction motor:7.5KW rated voltage:380V 50Hz Continuous (S1) working standard

3,electric heating power:100KW rated voltage:380V 50Hz Continuous (S1) working standard

4,oil pump power:3KW rated voltage:380V 50Hz Continuous (S1) working standard

5.glue pump motor power :2.2Kw

![]()

Preheater

*Technical parameters:

1,Effective width:1800mm

2,diameter of preheat roller:900mm

3,angle adjustment range:360°rotation

4,angle shaft diameter:110mm×2

5,steam temperature:150-180℃

6,steam pressure:0.8-1.3Mpa

7,equipment size:Lmx3.3*Wmx1.1*Hmx1.3

8,single weight:MAX1800Kg

9,working power:380V 50Hz

10,Motor power:250W short(S2)working system

![]()

Slitter scorer and cutter machine

*Technical parameters:

1,The maximum working width:1800mm

2,operation direction:left or right(Determined in accordance with customer plant)

3,The maximum mechanical speed:150m/min

4,Mechanical configuration:Computer spiral knife crosscutting

5,Cutting length:300-1800mm

6,Minimum slitting width:180mm

7,Precision Cutter:±1mm(Uniform) ±1.5mm(Non-uniform)

8,5 groups 200blades

*Roller diameter parameters:

1,Cross on the knife shaft diameter:200mm Balancing done deal

2,Cross under the knife shaft diameter:200mm Balancing done deal

3,Under the pull roller diameter:156mm Balancing done deal

Note: After all have been grinding rollers, hard chrome plated at (upper and lower arbor exception) processing.

![]()

![]()

![]() \

\![]()